Optical Fibre Diameter Analyser Devices for Lab and Field Use

Optical Fibre Diameter Analyser Devices for Lab and Field Use

Blog Article

Achieve Superior Lead To Fiber Optics With a Dependable Diameter Analyser

In the world of fibre optics, accomplishing remarkable results is fundamentally linked to the precision of diameter measurements. A dependable diameter analyser acts as a vital device, making certain that even minute variants in fiber size are spotted and dealt with, thereby securing signal stability and light transmission performance. The importance of these measurements expands beyond simple compliance; they are critical in enhancing manufacturing processes and fostering count on in end-user applications. As we explore the details of picking an ideal diameter analyser, the effects for overall efficiency and sector requirements warrant closer examination.

Value of Diameter Dimension

Accurately measuring the size of fiber optics is essential for guaranteeing optimal efficiency and integrity in telecommunications. The diameter straight affects the light transmission characteristics of fibre optic cords, influencing data transfer, signal stability, and total data transmission performance. Variations in size can lead to enhanced attenuation and diffusion, which can break down signal high quality and limit the reliable variety of interaction systems.

Additionally, compliance with market standards requires specific size dimensions to make certain compatibility with connectors and splicing techniques. Dissimilar sizes can result in raised insertion loss and port imbalance, resulting in possible system failings. Additionally, the production process of fiber optics calls for rigorous quality assurance steps, where size dimensions function as an important parameter for assessing product consistency and efficiency.

In high-stakes environments such as information facilities and telecommunication networks, the relevance of size measurement transcends plain conformity; it is important to keeping system reliability and efficiency - optical fibre diameter analyser. Hence, purchasing precise fiber optics size analysers is vital for producers and solution carriers aiming to support the highest requirements in telecoms infrastructure. Proper dimension methods can significantly boost the functional effectiveness of fiber optic networks, inevitably influencing individual experience and service distribution

Functions of a Top Quality Analyser

A high quality fibre optics size analyser is identified by several crucial functions that enhance its capability and integrity in gauging optical fibre sizes. Accuracy is critical; high-resolution dimension capabilities make sure that also the smallest variants in diameter are accurately identified. This is commonly helped with by innovative optical sensing units and calibration methods that decrease dimension error.

Another important function is user-friendly software that permits operators to easily analyze and examine information. Intuitive interfaces allow quick adjustments and setups adjustments, simplifying the measurement procedure. Additionally, several analysers come furnished with data logging and reporting functions, offering important understandings for quality assurance and compliance.

Toughness is additionally important, as fibre optic settings can be rough. A durable layout, commonly featuring safety cases and weather-resistant elements, guarantees dependable operation under differing conditions. Compatibility with various fibre kinds and sizes broadens the analyser's versatility, making it ideal for various applications.

Advantages of Accurate Measurements

Moreover, exact diameter analysis plays a vital function in high quality control throughout the production process. By guaranteeing that fiber optic wires satisfy specified size tolerances, manufacturers can reduce the risk of defects, which can result in expensive failings or downtimes in telecommunications systems. This dependability fosters confidence among customers and end-users, as they can trust the efficiency of the mounted systems.

Furthermore, precise size measurements assist in far better compatibility with connectors and various other parts in the fibre optic ecosystem. This compatibility is essential for smooth assimilation and optimal performance, eventually leading to minimized setup time and prices. optical fibre diameter analyser. In summary, precise size dimensions in fiber optics not just boost efficiency and reliability however likewise add to greater high quality criteria and boosted customer complete satisfaction in the competitive telecommunications market

Influence On Manufacturing Efficiency

In the realm of fiber optics manufacturing, the precision of size dimensions straight affects producing effectiveness. Precise size analysis guarantees that the optical fibres created meet strict specs, decreasing the chance of flaws that can cause pricey rework or scrap. When manufacturers apply reputable diameter analysers, they can recognize discrepancies in real-time, allowing for instant modifications to manufacturing procedures. This positive method lowers downtime and improves general throughput.

In addition, consistency in size measurements promotes uniformity in the final product, which is critical for preserving high-quality standards. Inconsistent diameters can impact the efficiency of fibre optic cables, leading to raised signal loss or degradation over time. By guaranteeing precise dimensions, producers directory can enhance item integrity, inevitably enhancing consumer satisfaction and reducing service warranty cases.

Purchasing innovative diameter analysers also simplifies the top quality control procedure. Automated information collection and evaluation help with fast decision-making and provide insights into manufacturing trends, better enhancing operational efficiency. In recap, the influence of precise size dimensions on producing performance is profound, as it not only maximizes manufacturing yet additionally enhances product high quality and dependability in the competitive fiber optics market.

Choosing the Right Diameter Analyser

Choosing the appropriate diameter analyser is pivotal for keeping the high standards developed in fibre optics manufacturing. The best analyser makes sure specific dimension of optical fibre diameters, which is vital for attaining optimum performance and reliability in final products.

When picking a size analyser, take into consideration crucial requirements such as dimension resolution, array, and accuracy. An analyser with a broad measurement variety can fit various fibre kinds, while high accuracy and resolution are important for detecting also small diameter variants that might impact performance.

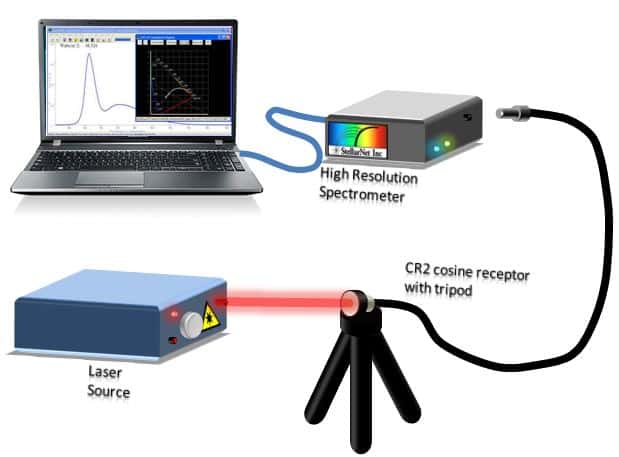

Additionally, examine the technology used in the analyser. Optical and laser-based analysers usually supply remarkable accuracy contrasted you could check here to conventional get in touch with methods. Look for attributes such as real-time data handling, easy to use user interfaces, and compatibility with existing manufacturing systems to enhance operational effectiveness.

Furthermore, think about the support and solution used by the producer. A trustworthy supplier will offer extensive training, maintenance, and technical help, guaranteeing that your team is geared up to utilize the analyser effectively.

Ultimately, investing in the best size analyser will certainly not only streamline manufacturing procedures but additionally make certain the distribution of high-grade fiber optic items to the marketplace. (optical fibre diameter analyser)

Verdict

Finally, the combination of a dependable diameter analyser is crucial for achieving superior outcomes in fiber optics. Accurate diameter measurements play a crucial function in guaranteeing optimal light transmission, minimizing defects, and boosting compatibility with adapters. The fostering of top notch analysers not just enhances manufacturing read this article effectiveness with real-time data processing however additionally sticks to rigorous sector standards. Inevitably, a commitment to exact measurement fosters depend on within telecommunications systems, benefiting both end-users and makers alike.

A trusted diameter analyser serves as an important device, making certain that also minute variants in fiber size are discovered and addressed, therefore safeguarding signal integrity and light transmission efficiency. Therefore, spending in exact fiber optics diameter analysers is crucial for suppliers and solution carriers aiming to maintain the highest standards in telecommunications infrastructure.A top quality fibre optics size analyser is identified by numerous crucial features that improve its capability and reliability in determining optical fibre sizes. In recap, precise diameter measurements in fibre optics not only improve performance and reliability yet likewise add to higher top quality criteria and enhanced consumer contentment in the affordable telecom market.

Report this page